In 2014 Maker Media contracted me to create a 3D printable replica of an 1872 patent model for their upcoming book ‘Inventing A Better Mousetrap’ about the Rothschild Patent Model Collection. The patent model I was reproducing, Patent# 122,944, was one in a series of improved electro-magnetic engines created by Claude Victor Gaume for Williamsburg, New York. Gaume was exploring ways to make a motor move by pulsing its electromagnets in sequence. In 1872, this entailed using a complex series of timing switches and contacts. Today the same task can be done by an controller ic the size of a grain of rice. This patent model, and its closely related siblings, is the granddaddy of the brushless motors that are all around you today.

The Original 1872 Electromagnetic Motor Pattent Model, from the Rothschild Petersen Patent Model Collection

My reproduction of Gaume’s model was faithful to the original configuration, but used an Arduino and mosfets to pulse the electromagnets. To make the project easily reproducible for Maker Media’s readers, I used only commonly available parts. The Electromagnets were made from cut down u-bolts wrapped with 22 gauge wire. This made for strong but inefficient electromagnets, true to the ones found in the original patent model. They required lots of current at a very low voltage to function properly. Out of necessity, I ended up driving the magnets with three D-Cell batteries wired in parallel, feeding the magnets 1.5v at nearly endless amperage. The at-tiny that controlled the sequencing and mosfets needed 5v to function properly. So I need two sets of batteries, one that provided 5v at nominal amperage, and one that provided 1.5v and huge amperage. Full build instructions for the Electromagnetic motor were published in Make Magazine.

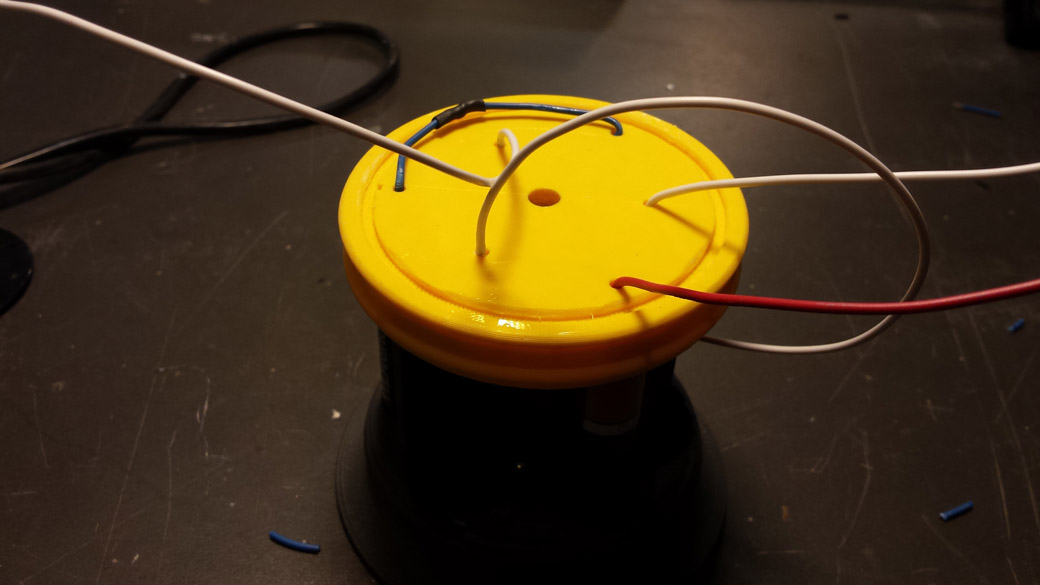

This Steampunk battery jar is what I came up with to contain the mess neatly. The mosfets and attiny fit inside the lid, and the four leads to the motor (three coils and a common supply) attach to the screw terminal on the top. It worked well and fit the overall look of the project.

Internally, the two sides of the battery share a common ground. which is carried by the long ¼-20 bolt that runs through the center of the battery. Unscrewing the bolt breaks the connection and lets you open the battery to remove the cells.

The 1/4-20 threaded screw is the common negative terminal for the batteries.

The nuts at the bottom of the battery and inside the upper cover have a ground wire soldered to them. Those wires connect to the negative side of the cells, and and the ground side of the controller.

I have tried various methods to make the contacts, including pennies, this method, hand soldered springs and washers, is less than optimal.

The three AA cells are wire in series to create approximately 5 volts. To keep the wiring neat, and avoid having another lead that has run between the top and bottom of the battery, one of these three cells is reversed.

The screw terminals at the top of the battery are M3 nuts and bolts. The long M3 bolts are attached to the wire inside the battery top, then locked into place with two counter-tightened nuts. The last nut is heated with a soldering iron, then pressed into the printed colored knob.

The top has a place for a switch, which can also be used as an opening for a USB port. This Battery doesn't have the motor control circuit inside it, i’ve just wired it up as a simple voltage source to have on hand for future projects. It looks great and has lots of space of whatever intelligence I eventually need to build into it.

If you would like to build your own Steampunk Multi-Voltage Battery Jar, you can download it from Thingiverse.

If you would like to build the my reproduction of the brushless motor patent model, you can download the files from Thingiverse, and find the instruction in Make Magazine.

To have the 3D Printed parts for this project delivered to your door, use this button to place an order through 3d Hubs.

The book ‘Inventing a Better Mousetrap: 200 Years of American History in the Amazing World of Patent Models’ is available from Amazon.