The Flywheel is an unseen hero with so many amazing abilities. They are used in everything from Uninterruptible Power Supplies to the Attitude Control systems of spacecraft. A Flywheel's angular momentum can be used to to resist or impart a rotational force, or to store large amounts kinetic energy for reuse.

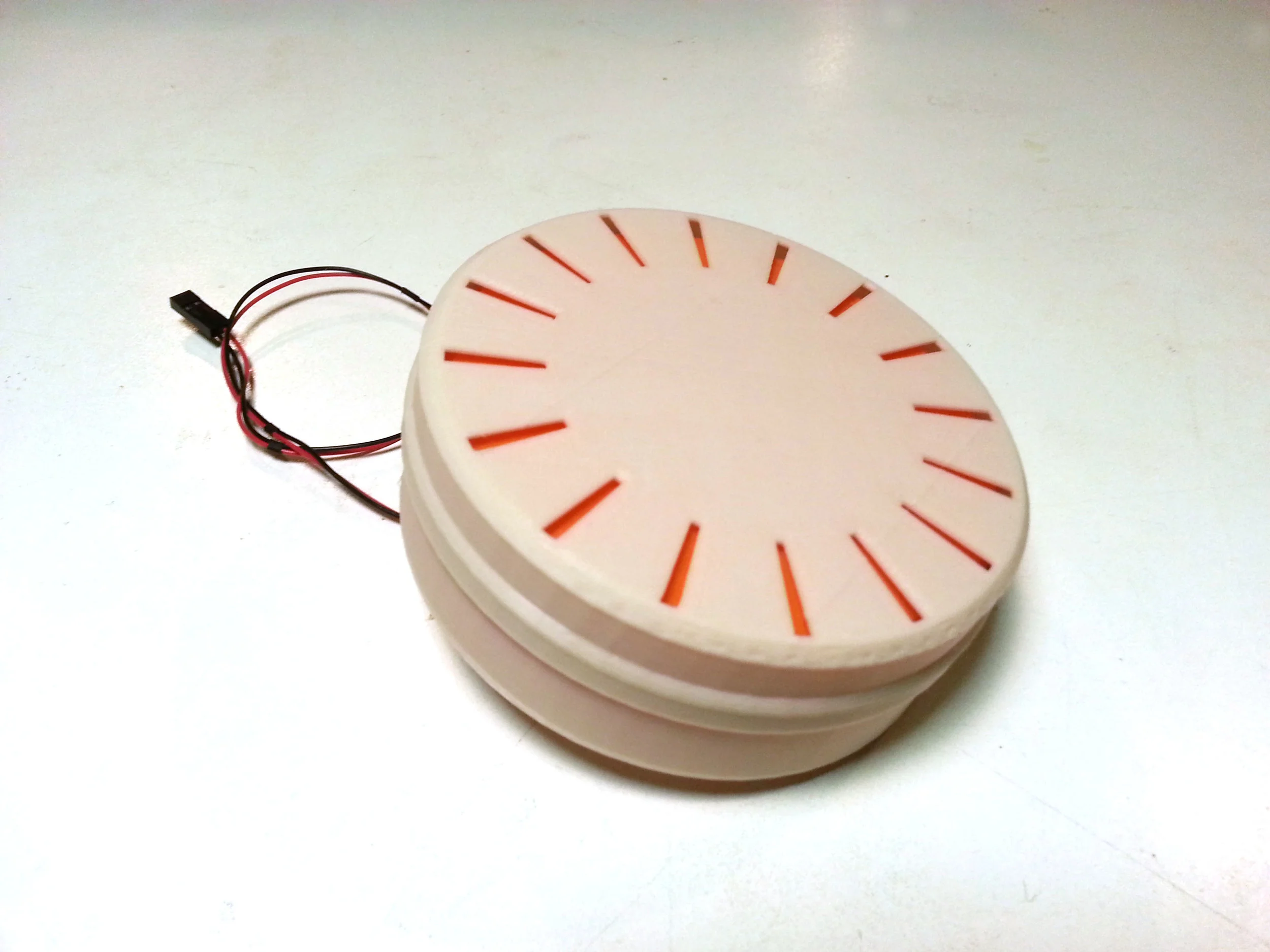

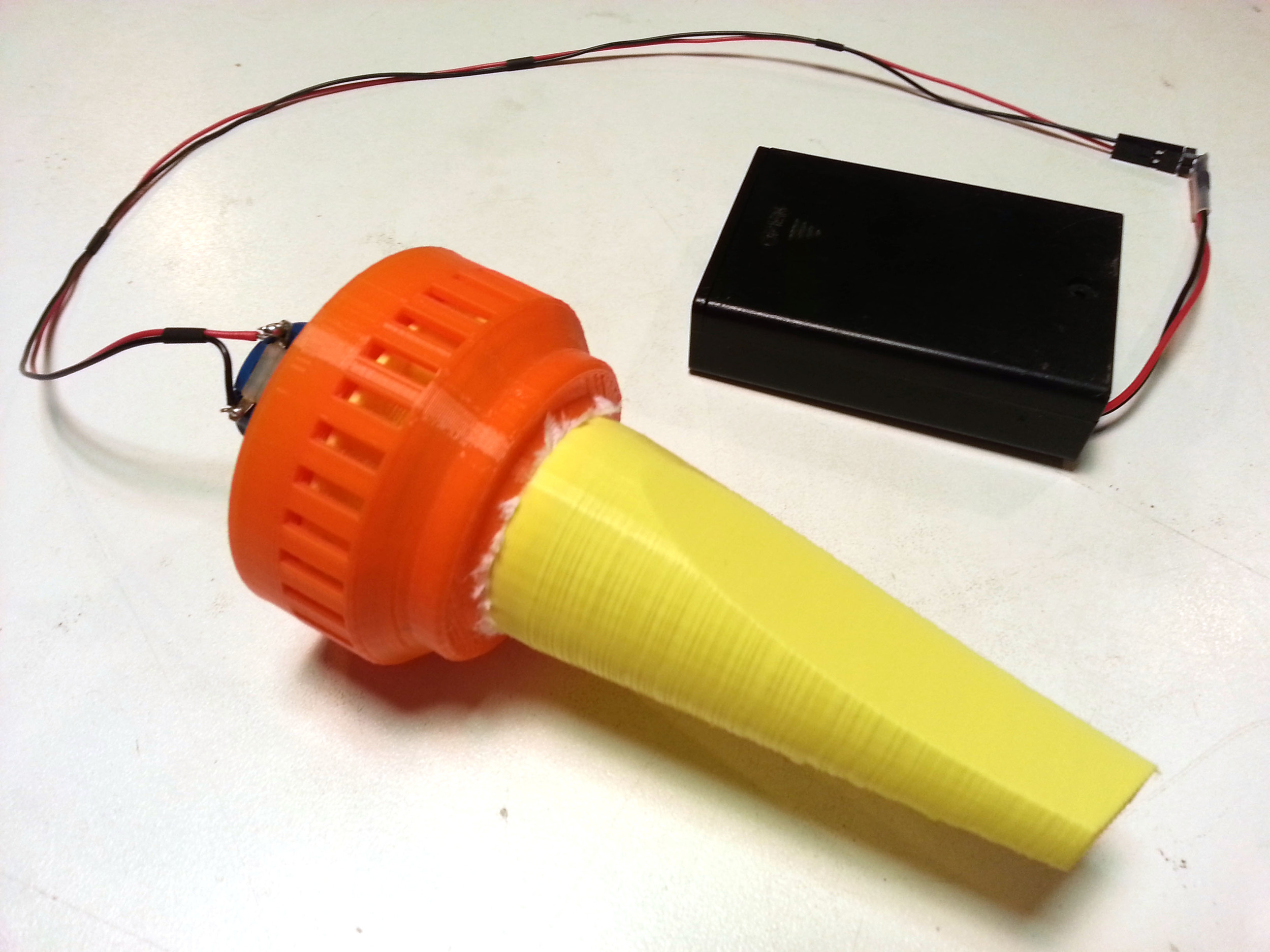

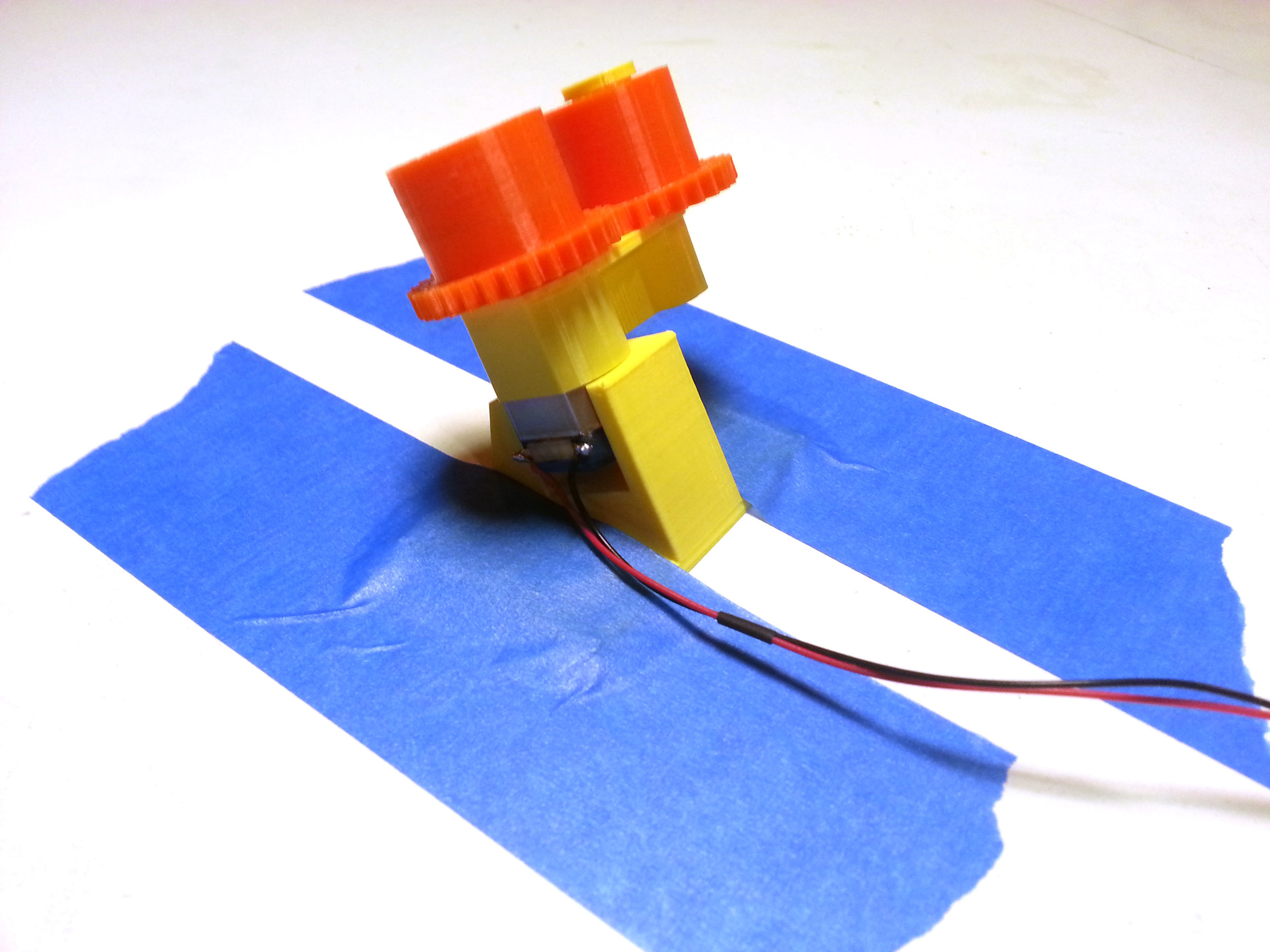

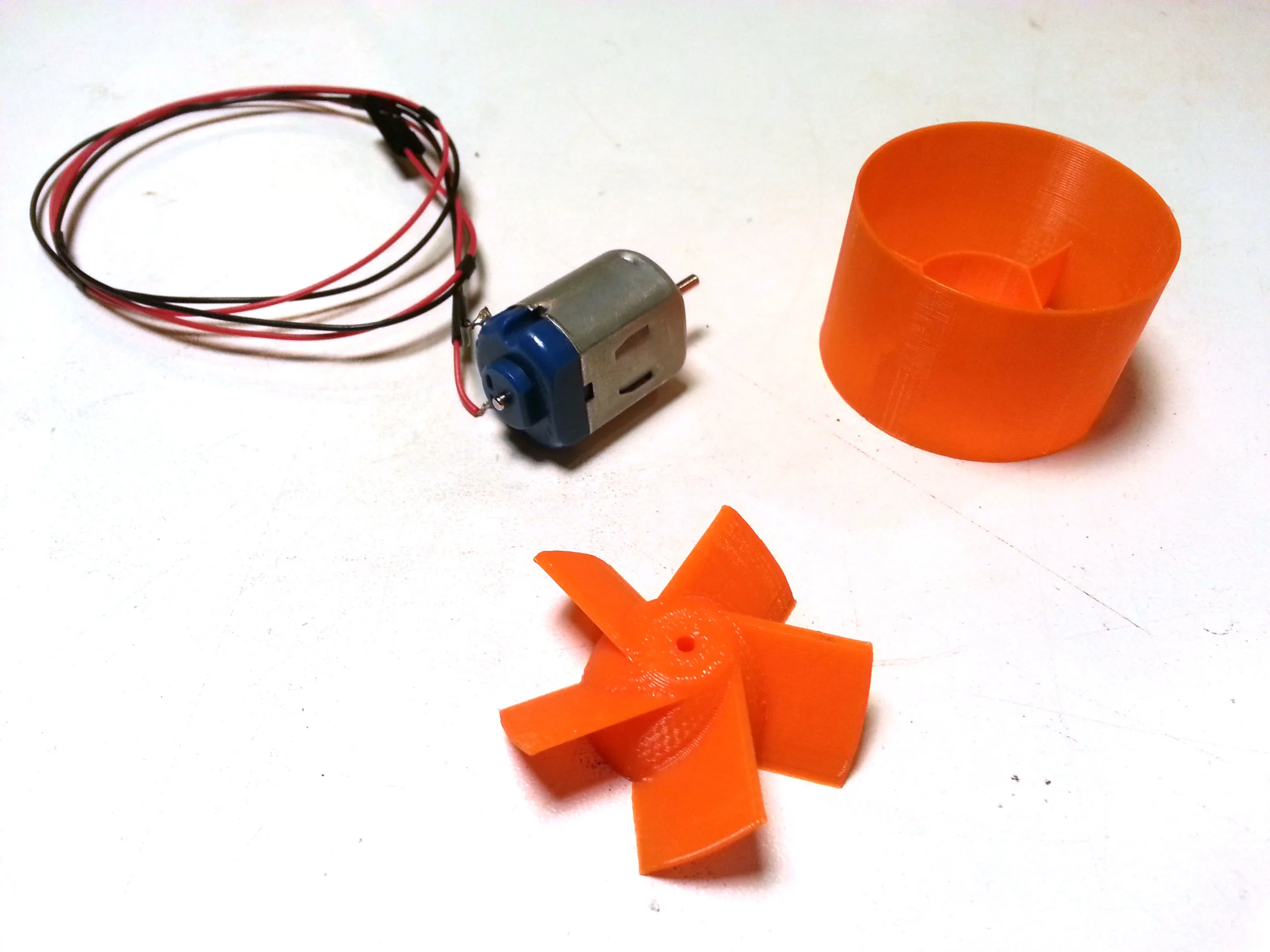

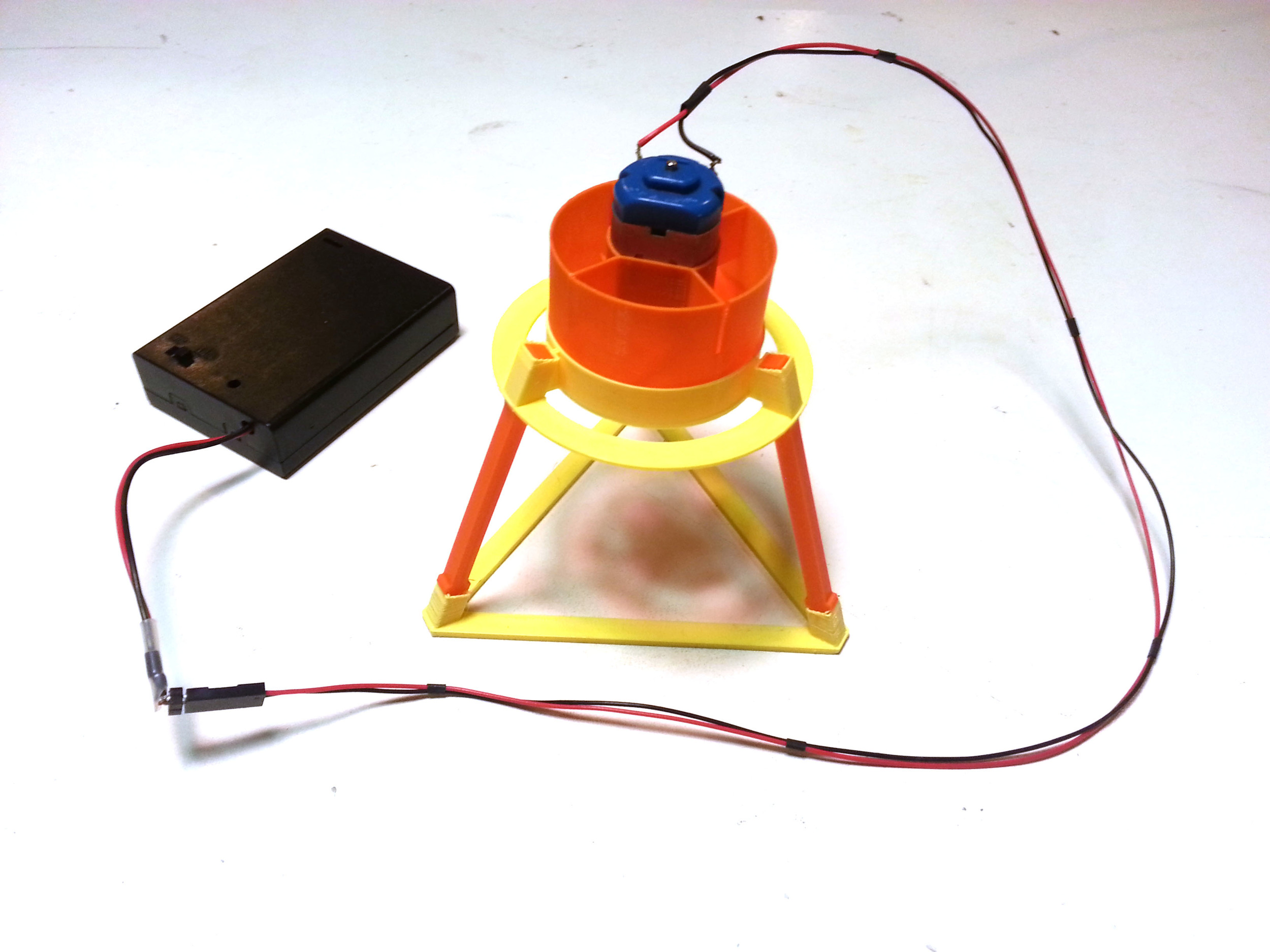

The mechanism behind this flywheel doesn't get much simpler. Its a spinning disk of mass contained within and enclosure. One of our little Fa-130 Motors spins the flywheel, and the enclosure lets us experiment without interrupting its rotation.

So what can we do with our flywheel? Well first and foremost, It makes a great gyroscope.

The spinning flywheel is resistance to changes in in it angular momentum. So you can easily balance it on its edge. Interestingly, because there is so much energy in the momentum of the spinning wheel, it will keep balancing on its edge for about a minute after power is removed.

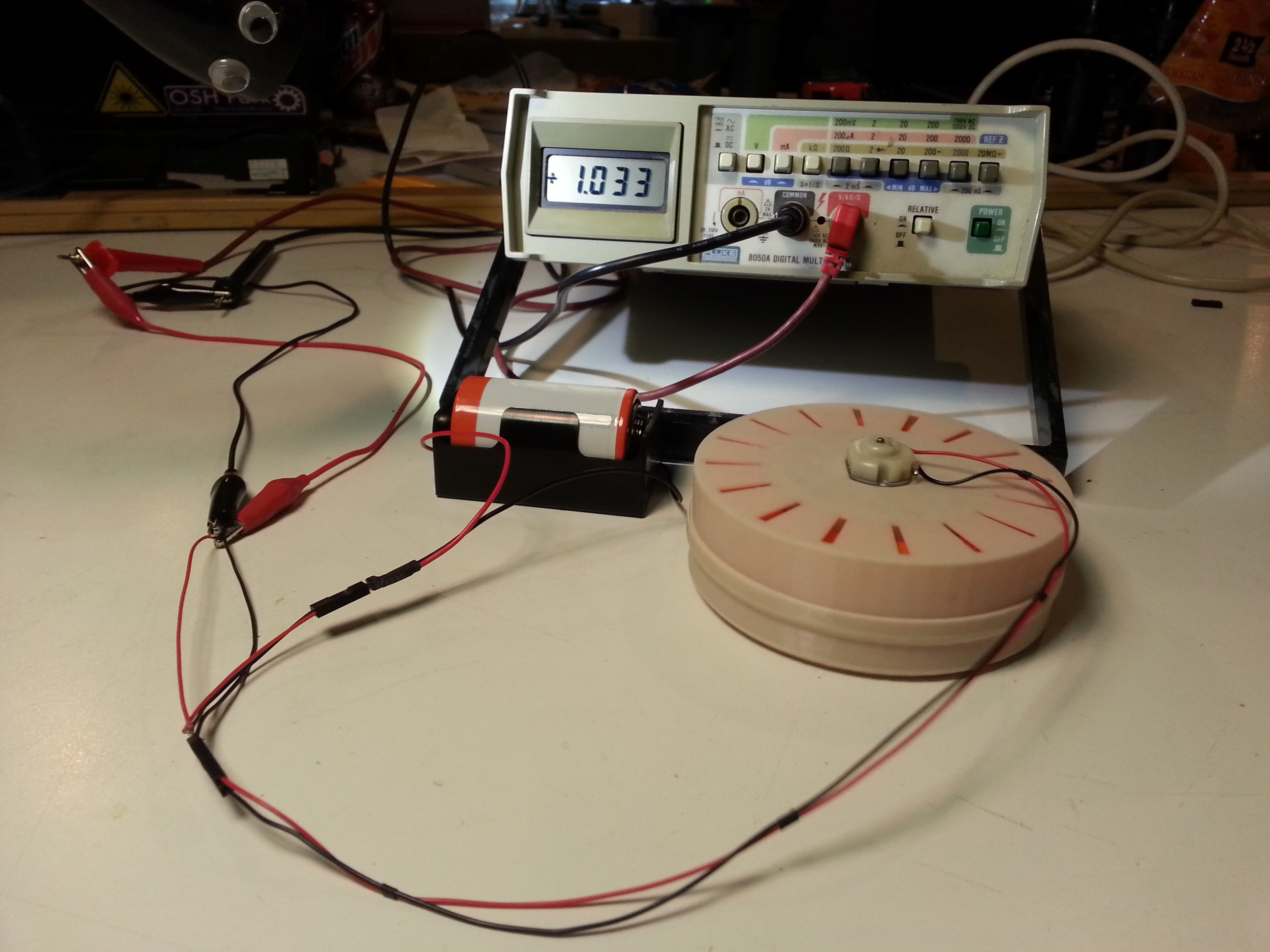

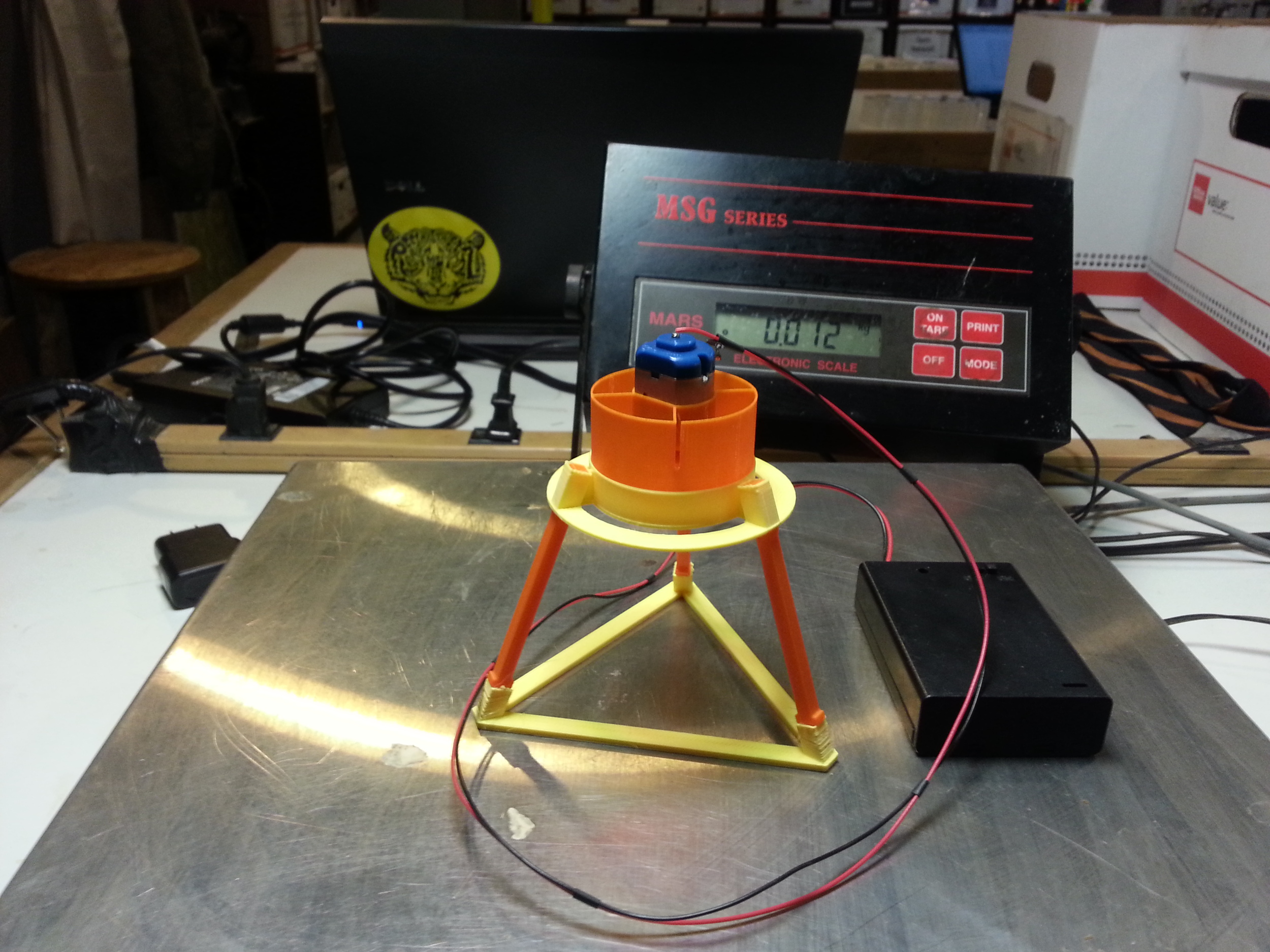

Electrical energy is being converted to kinetic energy by our little motor. That kinetic energy is stored in the momentum of the flywheel, and can be converted back to electrical energy. Like most DC Motors, the our little Fa-130 will also function as a small generator. To test this we'll need a voltmeter. Hammerspace has a nice one from Fluke.

With the Battery connected, the circuit shows 1.033 Volts. Where using a 1.5 Volt D-Sized Battery, but the voltage is being drawn down by the current demands of spinning the flywheel.

When the battery is disconnected, the meter shows 0.338 Volts. That is voltage being generated by our motor as its being spun by the flywheel. This little motor makes a poor generator, but we're still recovering almost a third of what was initially in the circuit.

As the Flywheels slows, the voltage produced drops. After 30 seconds, the flywheel is only producing 0.042 Volts.

This has been an interesting experiment, and if I get the time to revisit it I'd like to couple the Flywheel with an electronic controller to make a rudimentary Reaction Wheel.

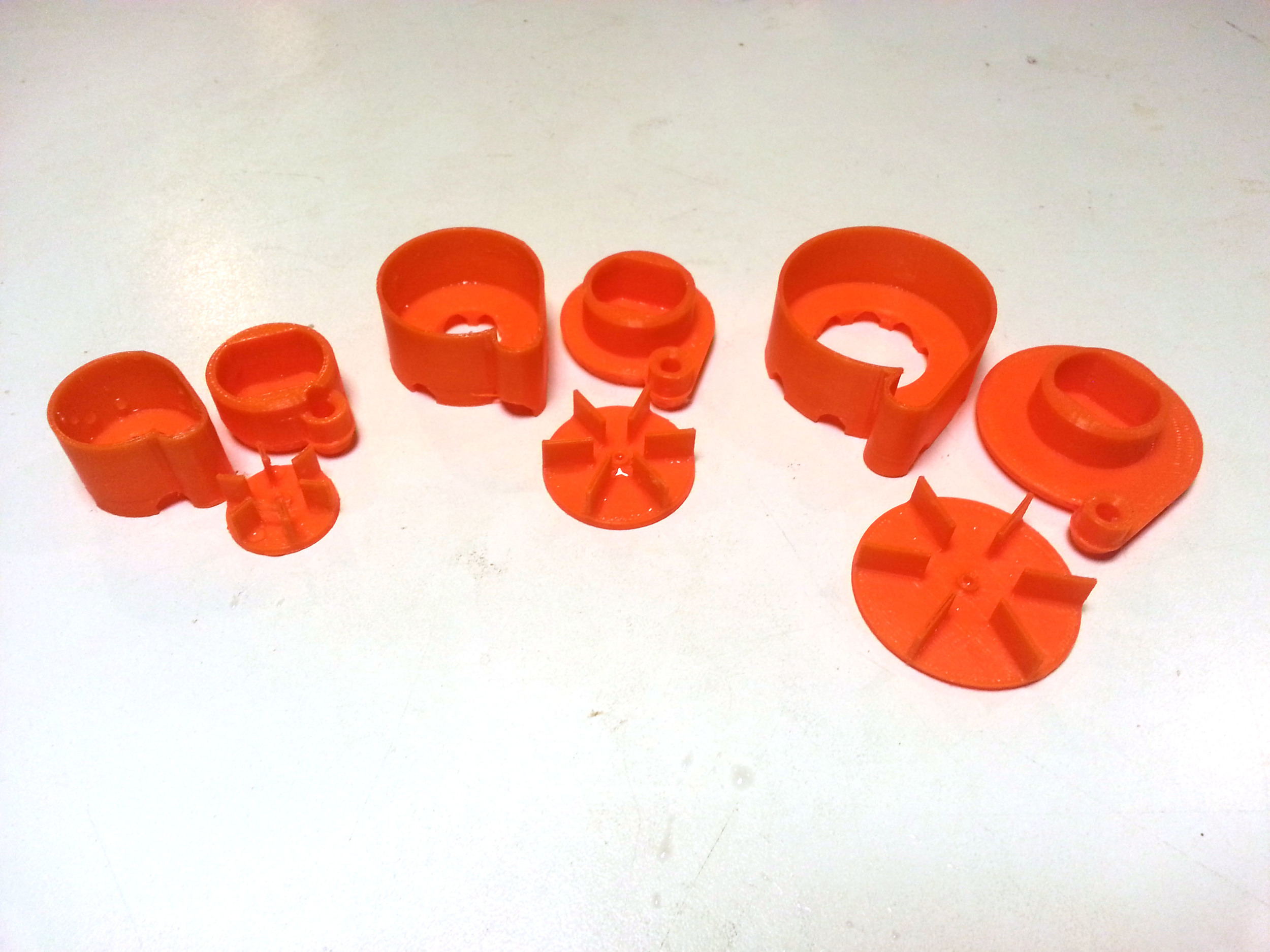

Download the Flywheel Files From Thingiverse: www.thingiverse.com/thing:557984

FA-130 Size Motor At Pololu: www.pololu.com/product/77